Packaging Engineer

In the packaging engineer role, there are several considerations to factor in, anything from launching new products to value engineering after a product launch to make sure the equipment is functioning properly. It's why the most trusted brands in the business choose to partner with us for their cheese and dairy packaging needs.

Regulatory Plant Certificates

At Printpack being an early adopter is kinda our thing, in order to certify all plant locations we use the GFSI and selected the FSSC 22000 and ISO 9001:2015 standard to occur in 2018.

Regulatory Plant Certificates

At Printpack being an early adopter is kinda our thing, in order to certify all plant locations we use the GFSI and selected the FSSC 22000 and ISO 9001:2015 standard to occur in 2018.

Product Formats

Printpack specializes in cheese and dairy packaging. We package sliced cheese, shredded cheese, greek yogurt, and much more. We offer high barrier food packaging through several packaging formats such as the stand-up pouch, retail bags, and institution shreds.

Available in a wide range of high-barrier packaging materials to meet your product's needs

Available in pre-made pouches or rollstock

Available in multiple styles, including Doyen

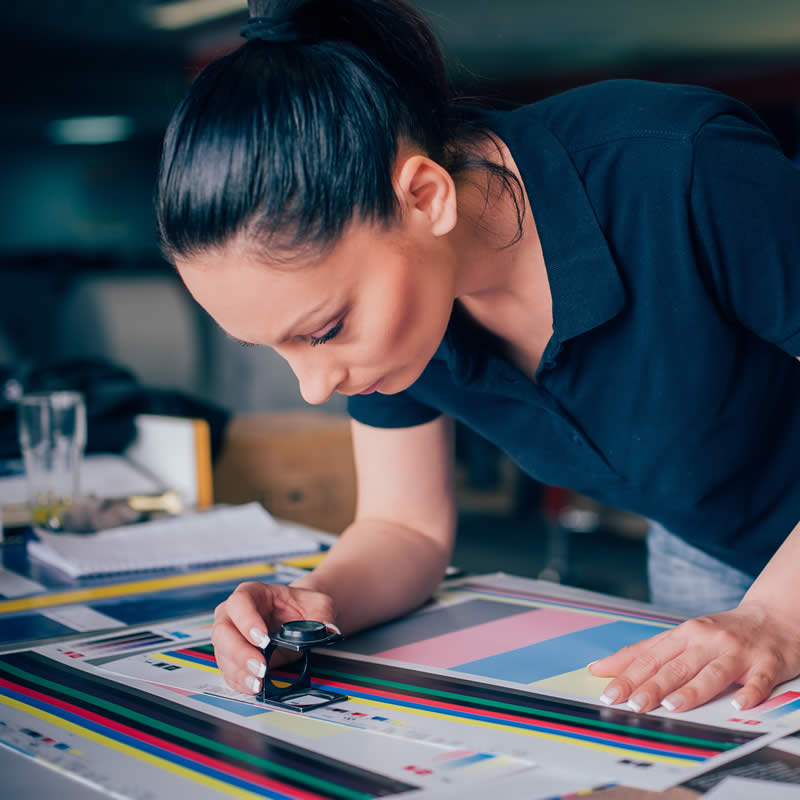

Film with outstanding optical properties in conjunction with high-fidelity printing

Convenience features such as easier scoring for easy open and slider zipper

Engineered materials lock out oxygen while locking in aroma and proper moisture levels for extended shelf life

Industry leading printing capabilities combined with our high-clarity materials for case appeal

Wide heat seal range for high-speed packaging

Consistent registration and wrinkle-free product

COF control for excellent slice stacking

Stiffer and tougher film for optimized packaging machinery performance

High-barrier, easy-open films keep cheese fresh and moist

Excellent formability and machine ability for operational efficiency

Different size fitments for different functions

Customizable barrier properties to meet your product's needs

Die-cut shapes and handles for shelf appeal and enhanced consumer experience

Environmentally friendly with reduced carbon footprint

Tamper evident for consumer safety

Packaging suitable for retort, hot-fill, HPP, and aseptic processes

Customizable barrier properties to meet your product's needs

Stock or customized design options for preformed cups

Microwaveable for convenient heat-and-eat products