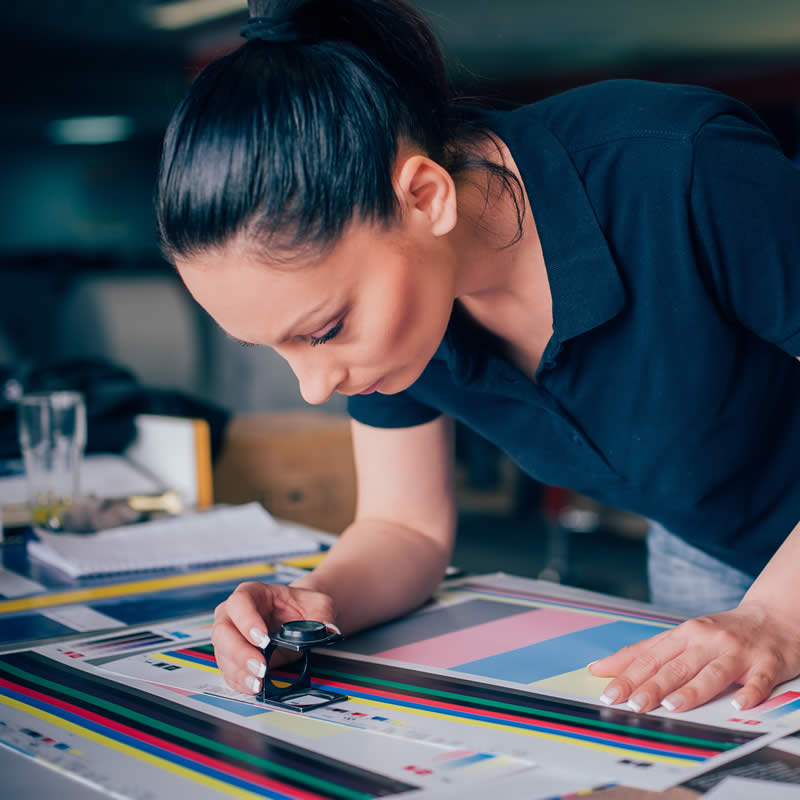

Packaging Engineer

In the packaging engineer role there are several considerations to factor in, anything from launching new products to value engineering after a product launch to make sure the equipment is functioning properly. It's why the most trusted brands in the business choose to partner with us for their medical packaging needs.

Regulatory Plant Certificates

At Printpack being an early adopter is kinda our thing, in order to certify all plant locations we use the GFSI and selected the FSSC 22000 and ISO 9001:2015 standard to occur in 2018.

Regulatory Plant Certificates

At Printpack being an early adopter is kinda our thing, in order to certify all plant locations we use the GFSI and selected the FSSC 22000 and ISO 9001:2015 standard to occur in 2018.

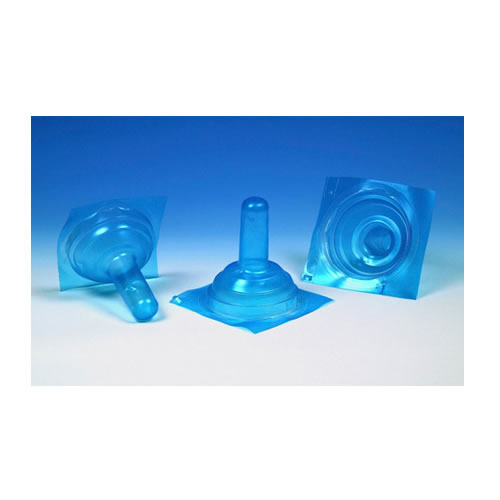

Product Formats

Printpack Medical manufactures a broad line of packaging products, including bags, forming films, and laminations and pouches, all compatible with EtO gas, radiation, and e-beam sterilization for medical devices, hospital supplies, and labware. Printpack is headquartered in Atlanta, Georgia (USA), and their primary medical manufacturing facility is in Marshall, North Carolina. Printpack Medical is ISO 13485 compliant, and their converted products are manufactured in compliance with an ISO Class 8 Cleanroom classification.

Easy-open center strip package designs allowing for convenient aseptic product removal

Package design available with side gussets for high-profile medical devices

Center strip allows package to be opened incrementally, creating a convenient storage vessel for use in a sterile environment

Packaging designs for EtO gas, radiation, and e-beam sterilization

Available with a peelable poly, paper, or KwikbreatheTM Tyvek® strip

Customizable, fiber-free peel seal made with either DupontTM Tyvek® or medical grade paper

Foil pouches

Foil/header pouches

Specialty pouches using a variety of substances including PET, nylon, foil, and AiOX for improved barrier and mechanical performance

Breathes 2-3 times faster than competitive products

Allows for aseptic removal of contents

Controlled peelability, plastic-to-plastic easy-open peel seals

Package designs for EtO gas, radiation, and e-beam sterilization

Breathes 2-3 times faster than competitive products

Allows for aseptic removal of contents

Controlled peelability, plastic-to-plastic easy-open peel seals

Package designs for EtO gas, radiation, and e-beam sterilization

Packaging design with score-line technology for fast and easy-snap tear opening

Package designs for EtO gas, radiation, and e-beam sterilization

Available option of paper KwadventTM breathing system for improved breathability during gas sterilization and post sterilization venting

Package designs for EtO gas, radiation, and e-beam sterilization

Available with customizable print on bag or strip surface