Sustainable Packaging

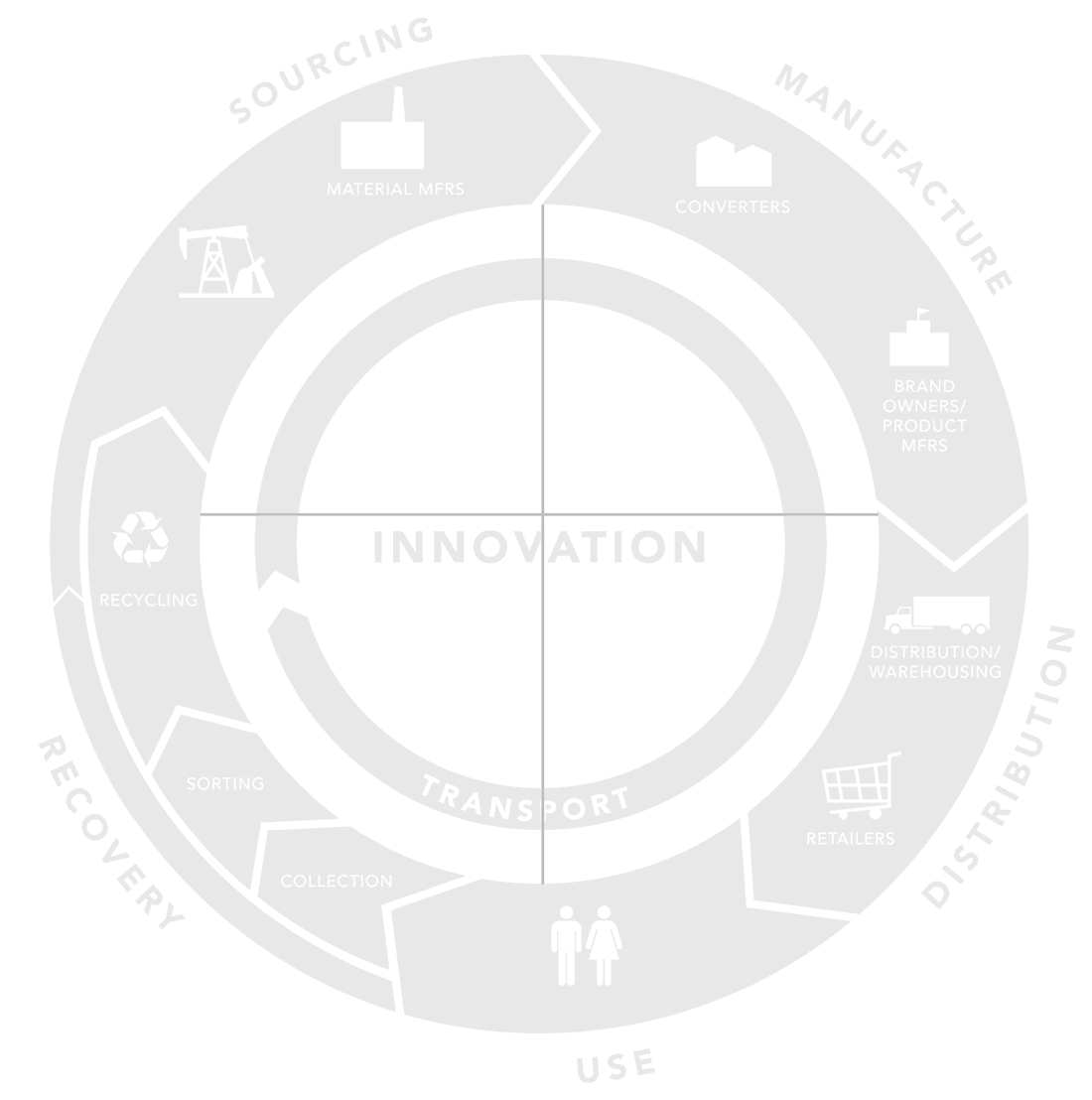

More now than ever before, brands in all categories are being challenged to use packaging and processes that reduce emissions, minimize waste, and consume fewer natural resources.

We help brands do this by advancing our Purpose and Philosophy through the Four Ps:

People, Plants, Products, and Partnership as it relates to sustainable packaging.

Consult with Printpack for the latest sustainable packaging technology:

- High-performance materials and re-close technologies

- Rigid containers made from curbside PCR

- Recyclable pouches, rollstock, and containers

- New and emerging biomaterials

- Source-reducing package design

- Industrially compostable packaging

People

There is one crucial component that has attributed to more than 60 years of success at Printpack — our people. Our associates work closely with customers to develop sustainable packaging that will safeguard their products in the most responsible way possible.

Printpack helps customers achieve their packaging goals. This vision is brought to life by dedicating sustainable packaging thought leaders to the full-time pursuit of packaging innovation.

Plants

Printpack is committed to developing and using sustainable systems in our daily manufacturing operations that ensure the highest possible standards in plant emissions, waste reduction, and consumption of natural resources.

Coming Soon – Printpack Sustainability Goals for 2030

Printpack Preserve™ is our commitment to:

- developing and supplying sustainable structures that use post-consumer recycled (PCR) content

- maximizing opportunities for source reduction

- reducing greenhouse gas emissions

- designing for optimal end of life options such as recyclability and compostability

Sustainability Benefits of Packaging

Flexible and specialty rigid packaging offers a number of sustainability benefits throughout the entire life cycle of the package when compared to other packaging formats including:

Reduced

- GHG emissions

- Materials to landfill

- Food waste

- Packaging materials

Improved

- Resource efficiencies

- Storage footprint

- Product-to-packaging ratio

- Transportation benefits

BEGINNING OF LIFE PACKAGING

Renewable Content

- Reduce dependency on petrochemicals

- USDA biobased product

- Demonstrated commercial success

PCR

- Increased demand for recycling and drive the circular economy

- Packaging contains recycled plastics (primarily PET, HDPE, PP)

- Developing commercial structures

Recyclable

- Today’s most viable circular solution

- How2Recycle certified packaging

- Demonstrated commercial success

Industrial Compostable

- When recycling is not an option or to meet legislation requirements

- Utilize to help meet food waste goals

- Developing commercial structures

NEXT LIFE PACKAGING

Flexible Packaging Compared to Other Packaging Formats

Carbon Impact

A rigid PET container for laundry detergent pods emits +726% more greenhouse gases than a flexible pouch with a zipper.

Fossil Fuel Usage

A rigid pail for cat liter packaging consumes +1,429% more fossil fuel than a flexible bag.

Water Usage

An HDPE bottle for motor oil packaging consumes +513% more water than a flexible pouch with a fitment. A steel can for packaging coffee consumes +1,605% more water than a flexible pouch.

Product to Package Ratio

A single-serve juice flexible pouch efficiently uses packaging with a product to package ratio of 97% compared to a can.

Material to Landfill

+31% more thermoformed tubs for food packaging end up in landfill compared to a flexible pouch.

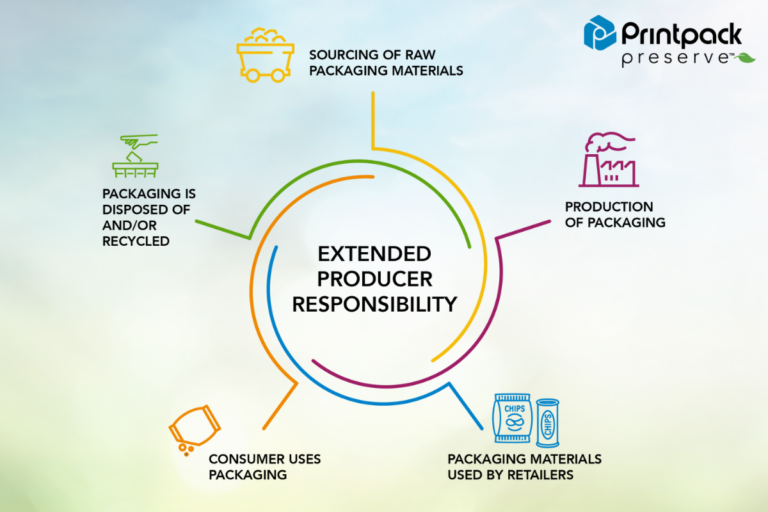

Partnerships

We have established partnerships with non-governmental organizations to broaden our expertise and build more credibility with clients.